We build with quality hardwood and custom cut and finish products based on style and intended use

Edge style options for your custom counter top

Cambium Wood Technologies, our standard -default- edge is square, sanded lightly at 1/16” to remove any sharpness. This edge style is excellent where a countertop will abut a wall, for example. If you like to consider edge styles with a bit more visual interest, such as Eased, Beveled, 1/4” inch Radiused or Cove. For a timeless look, think about the elegant Radius & Step edge design, Full Bull nose edge or the classic Roman Ogee.

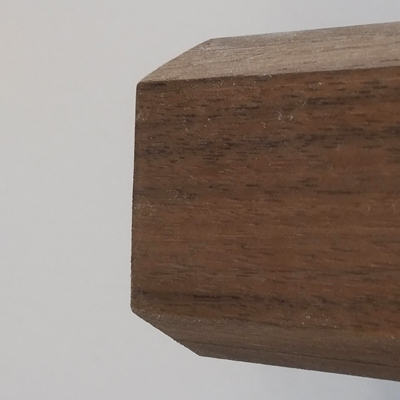

Bevel

Bevel

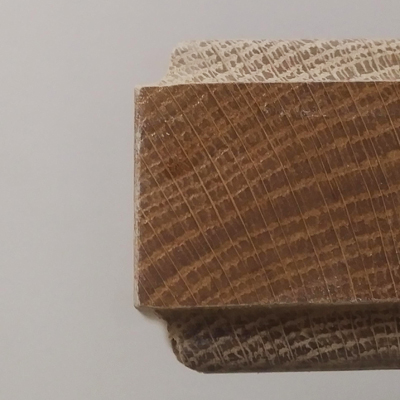

Bull nose

Eased

Ogee

Radius

Natural Oil is our standard finish on countertops, islands and chopping blocks. It is a food safe mineral oil suitable for day-to-day cutting or chopping. Reapplication is required to maintain and protect the seal and keep the surface pristine over years of use.

Various lacquers are used to finish products that are not used for cutting. They are water resistant and can be glossy or matt. Lacquer finishes provide a highly protective coat that is hassle and maintenance free.

All our products are built using Titebond III glue that is approved as food safe and waterproof. Butcher block cutting boards and chopping blocks are treated with a pharmacy grade, food safe mineral oil to ensure water resistance and products are hand buffed with beeswax to give lustre and additional protection.